Track360 is an automatic Helper Code Print & Check, to ease the aggregation of bottles on downstream machines (case packer or bundling machines): the machine resolves the complexity of reading a pre-printed serialized code on randomly oriented round containers.

A key point of this solution is that it allow to print the Helper code in an easy-to-read position, for a direct aggregation of bottles-to-case or bottles-to-bundle on the downstream machine.

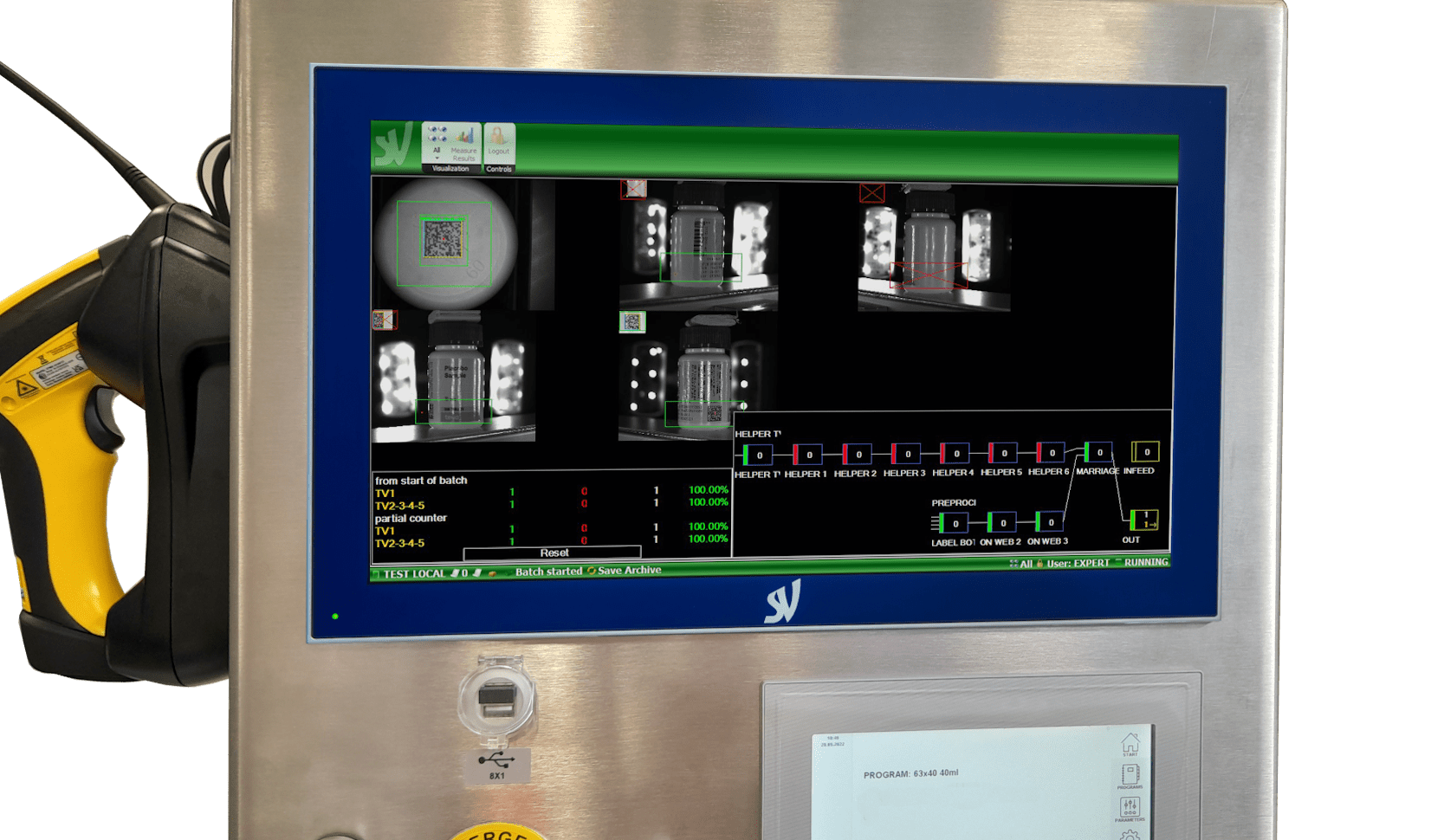

Helper code print & check machine

Helper code pairing with serialized code, to ease aggregation

360° inspection of round containers

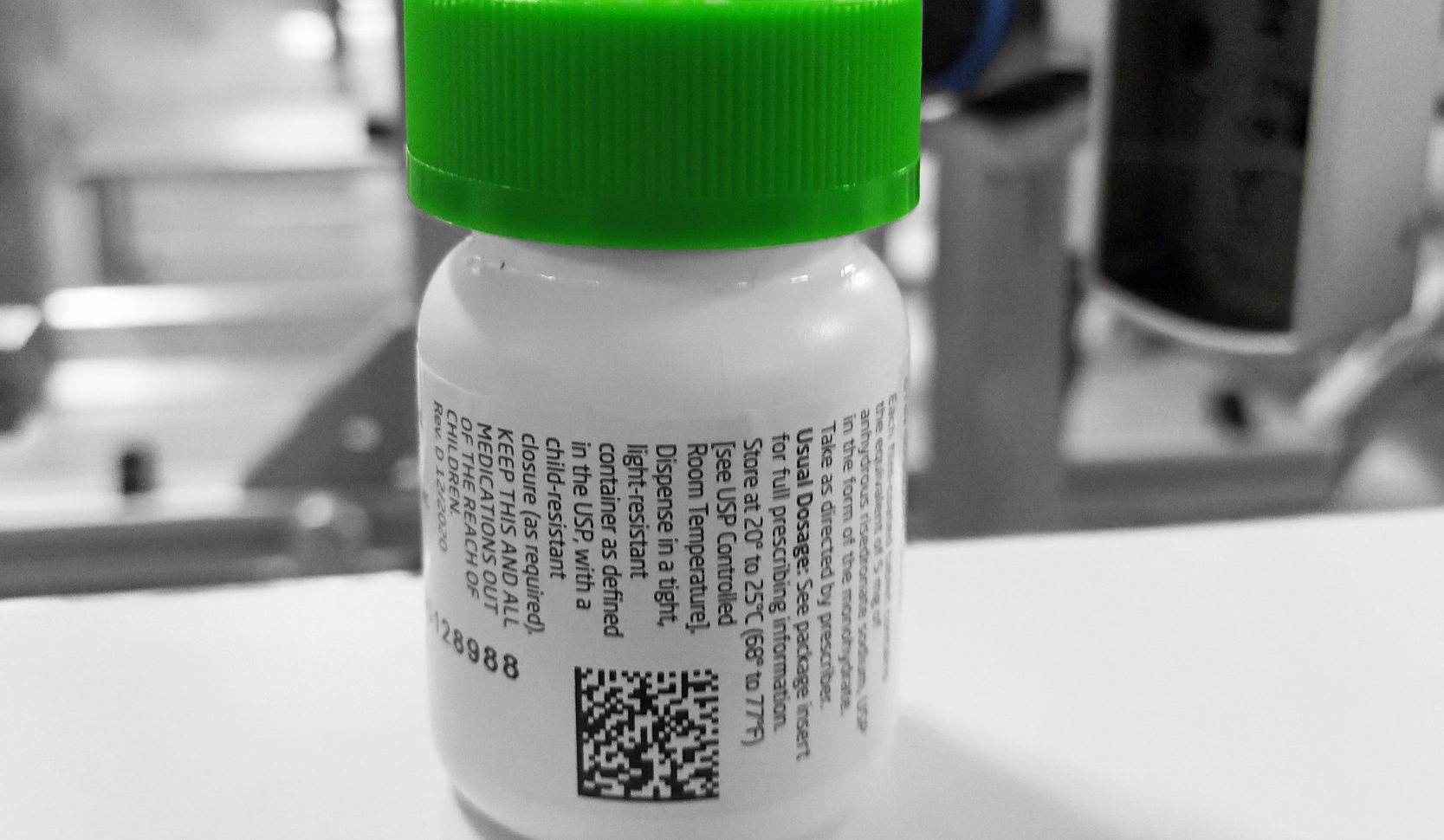

Reading of serialized codes on labels

Reworking operations

The purpose of the machine is to make possible the direct aggregation of round containers to a case or to a bundle in a bundling machine or case packer. This makes Track360 ideal for customers who must aggregate in environments having a high level of automation.

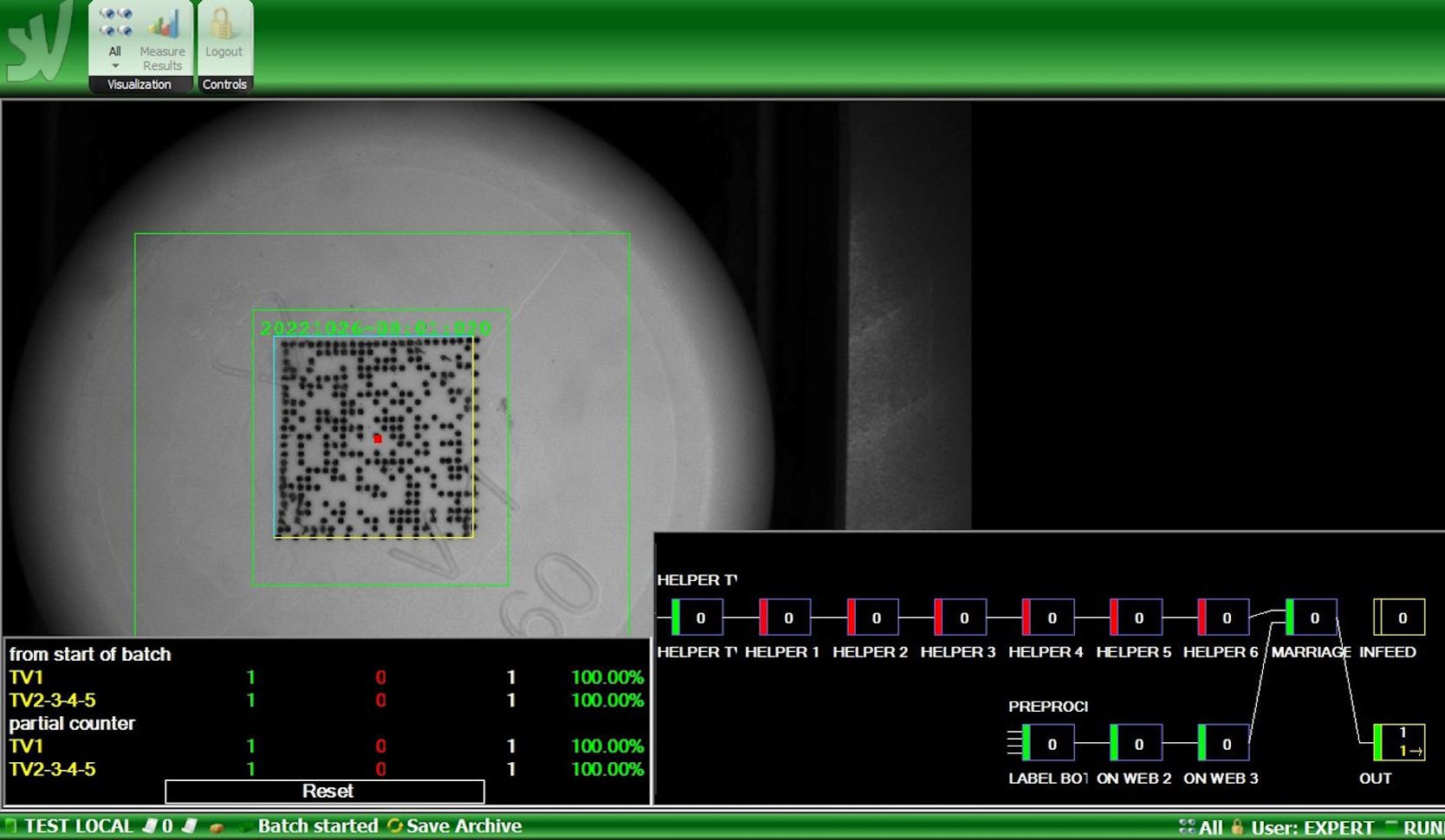

The operating workflow starts with the printing of a Helper Code on the bottom of the bottle which is then inspected by a camera with LED ring light.

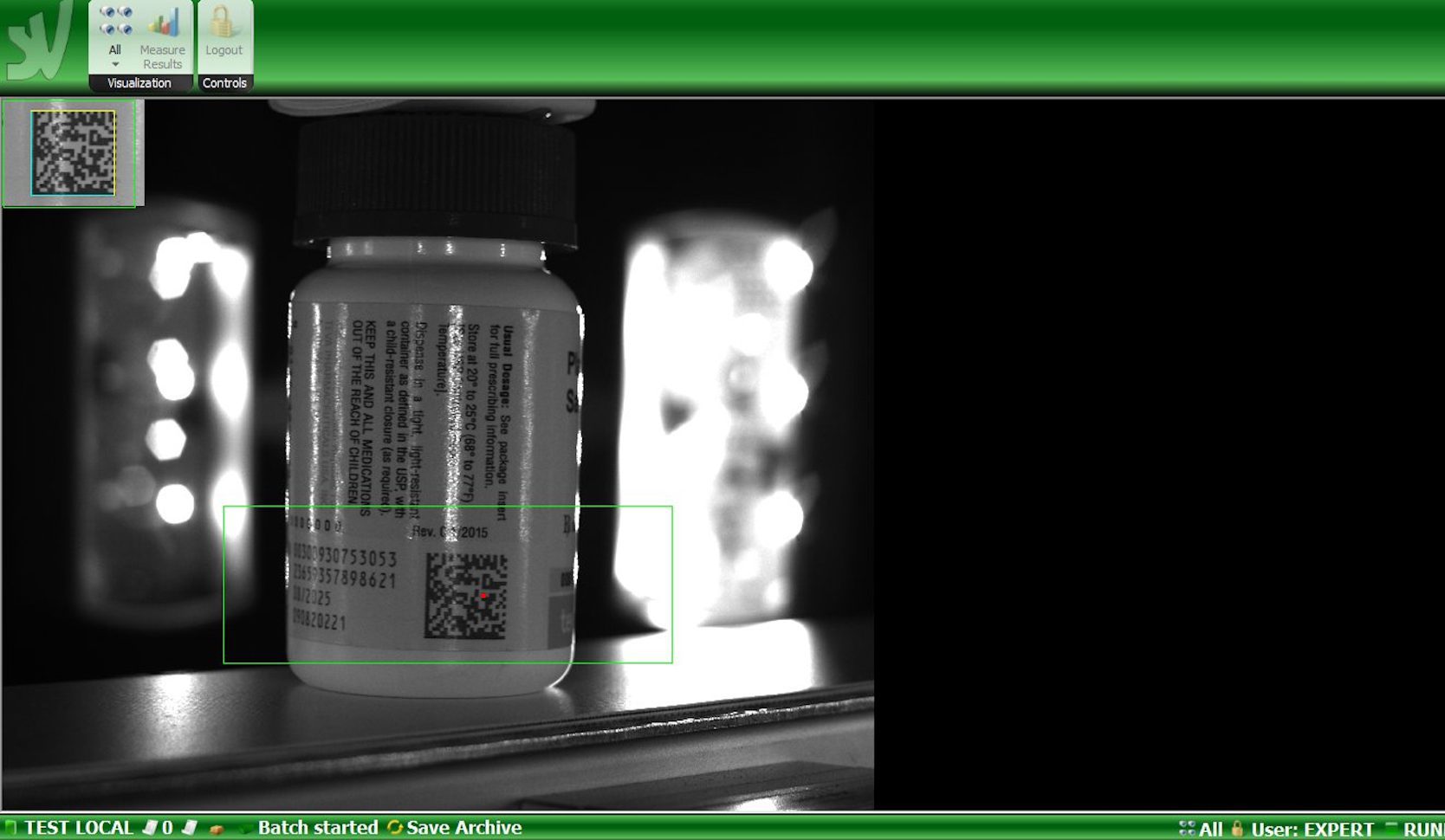

Additionally, in a second station, the system performs a 360° control around the bottle to read the label’s serialized code and to perform the pairing with the helper code. The correct products proceed toward the downstream machine, where the parent-child relation between bottles and case (or bottles and bundle) is created thanks to the reading of the helper code.

The machine features a compact stainless steel design with an integrated electrical cabinet, Hi-res cameras with LED lights, and movable touch screen HMI.

The system is specifically designed for the pharmaceutical market, and it is compliant with the industry regulations, with user access regulated by FDA 21 CFR part 11 and annex 11. All events are registered by the software in an audit trail file to keep track of all the security-relevant activities.

The continuous Software development follows Gamp 5, to always improve products quality and consistency.

The machine includes Tracker, a powerful serialization system, completely developed in-house by SEA Vision. Tracker is capable to perform complete sets of inspection on 1D, 2D codes, data matrix and OCV/OCR controls on characters in a completely trusty way. Tracker has a complete set of functionalities to perform serialization operation at machine level and perform the pairing between the helper code and the serialized code on the round container label.

The great advantage of Tracker is also the automatic correction of the code deformation that can affect an image of a round surface.

The software is natively integrated with the complete SEA Vision serialization and aggregation solution and is able to connect itself to the software that are necessary to manage line and plant level of serialization and aggregation.

The software Track360 is natively integrated with Yudoo, the 4.0 pharmaceutical software suite for the full management of automation processes, digital quality, data analysis and for Track&Trace. A digital hub that is everywhere accessible through a secure-access web interface or dedicated devices.

A scalable and modular suite, including tools for automation (centralized management of production, workflows and timesheet), for the digital quality (creation of paperless systems, support systems for line clearance operations), for data analysis (analysis of production data, business intelligence dashboard, condition monitoring and predictive maintenance) and for Track and Trace (complete solutions for Level 3 and 4 of serialization, monitoring of serialization operations).

Yudoo offers multiple advantages such as the possibility to centralize production formats and data, avoiding duplicates and reducing work time. The suite can connect to existing company systems to retrieve updated data exactly from where they are.

SEA Vision provides an extensive product portfolio of natively integrated solutions. Vision, traceability and data management solutions for pharmaceutical packaging lines are developed with a common approach to obtain a seamless ecosystem.