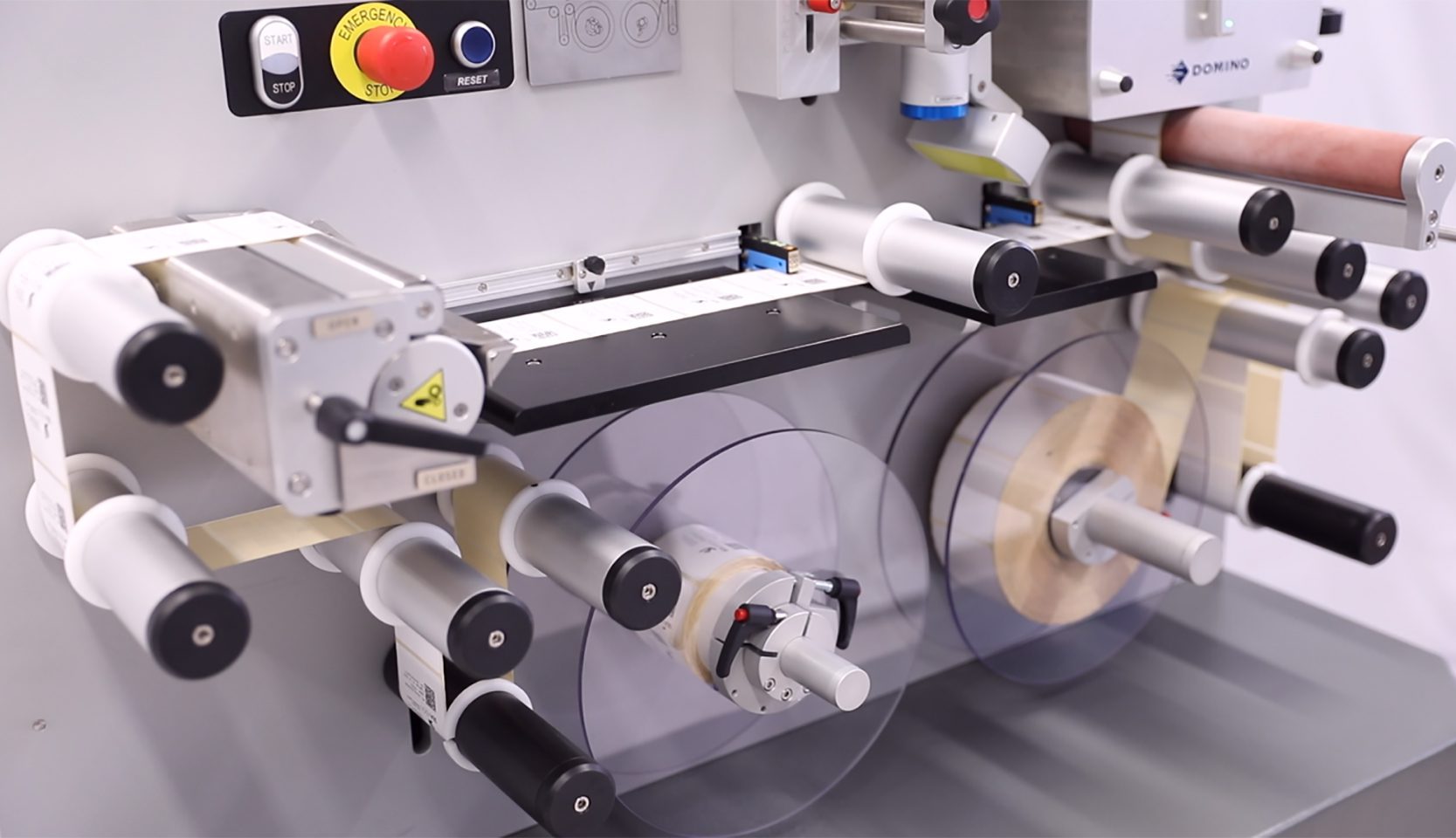

Trackroll is a stand alone Roll-to-roll workstation conceived to print and serialize labels reels. A module to provide in-house, on-demand, and high-quality inspected labels reels, ready to be then applied on your product, such as bottles, vials, cartons, etc, whenever and wherever you need.

Roll-to-Roll labels print

Offline labels serialization

Labels marking and inspection

Portable unit

Easy to use

Trackroll is an appealing pharmaceutical label printing machine for existing packaging lines in which there is a lack of space and that need to meet serialization requirements, becoming compliant in a fast way. The software of Trackroll supports the setting of different labels formats, characters and codes, to answer T&T requirements in different Countries.

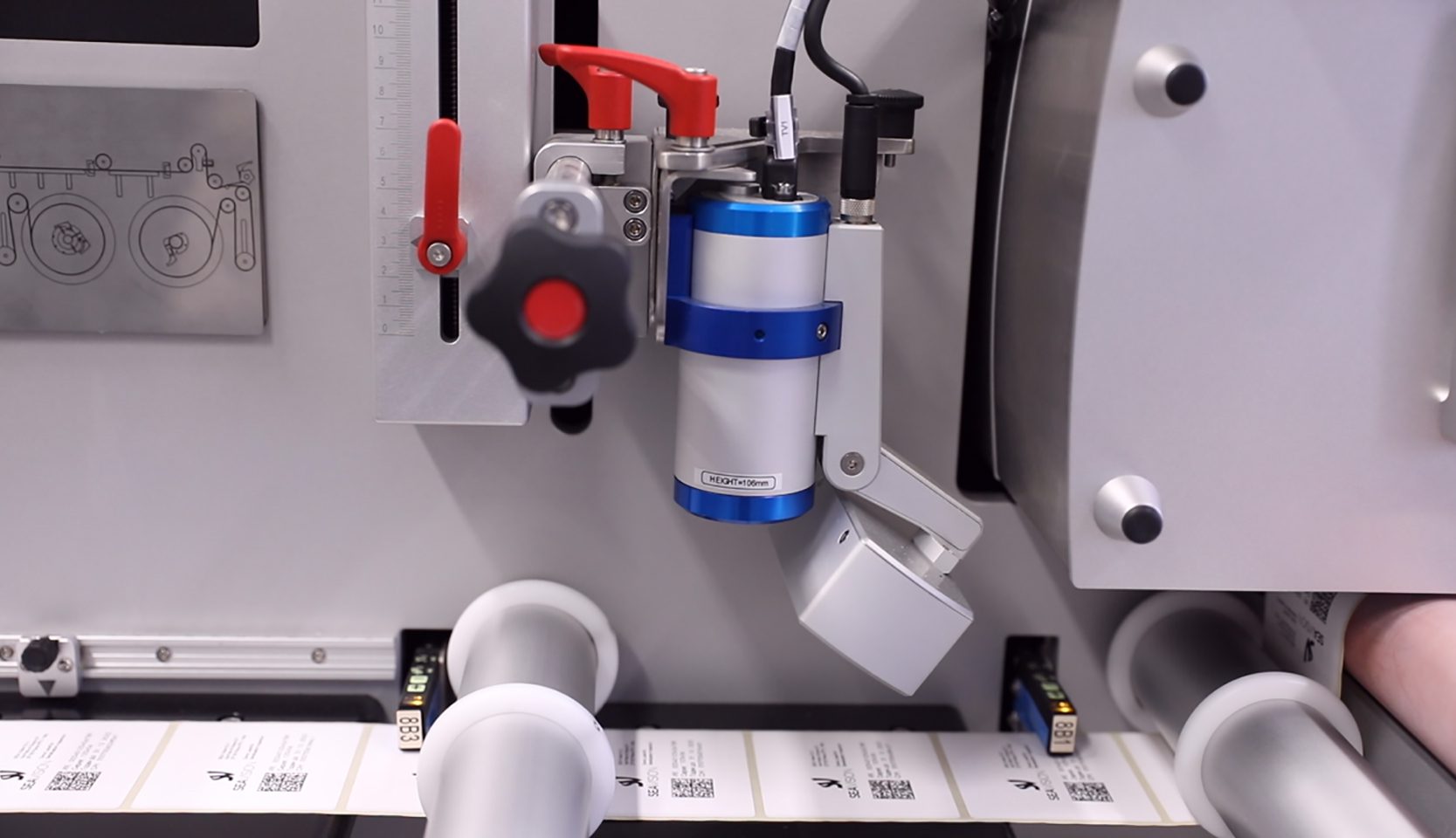

The first step of the machine workflow consists in packaging Labels printing and verification: Trackroll supports the printing and inspection of variable data, serialized or not serialized codes. It manages ANSI grading control in real-time and can manage PQV controls on pre-printed artworks on label reels. The installed software and the integration with the machine PLC, grant the highest quality inspection procedures and a defects-free production. After coding and verification, the reel is finally rewound and ready to be moved on production to be used on the packaging lines in order to apply only good labels on the final unit of sale.

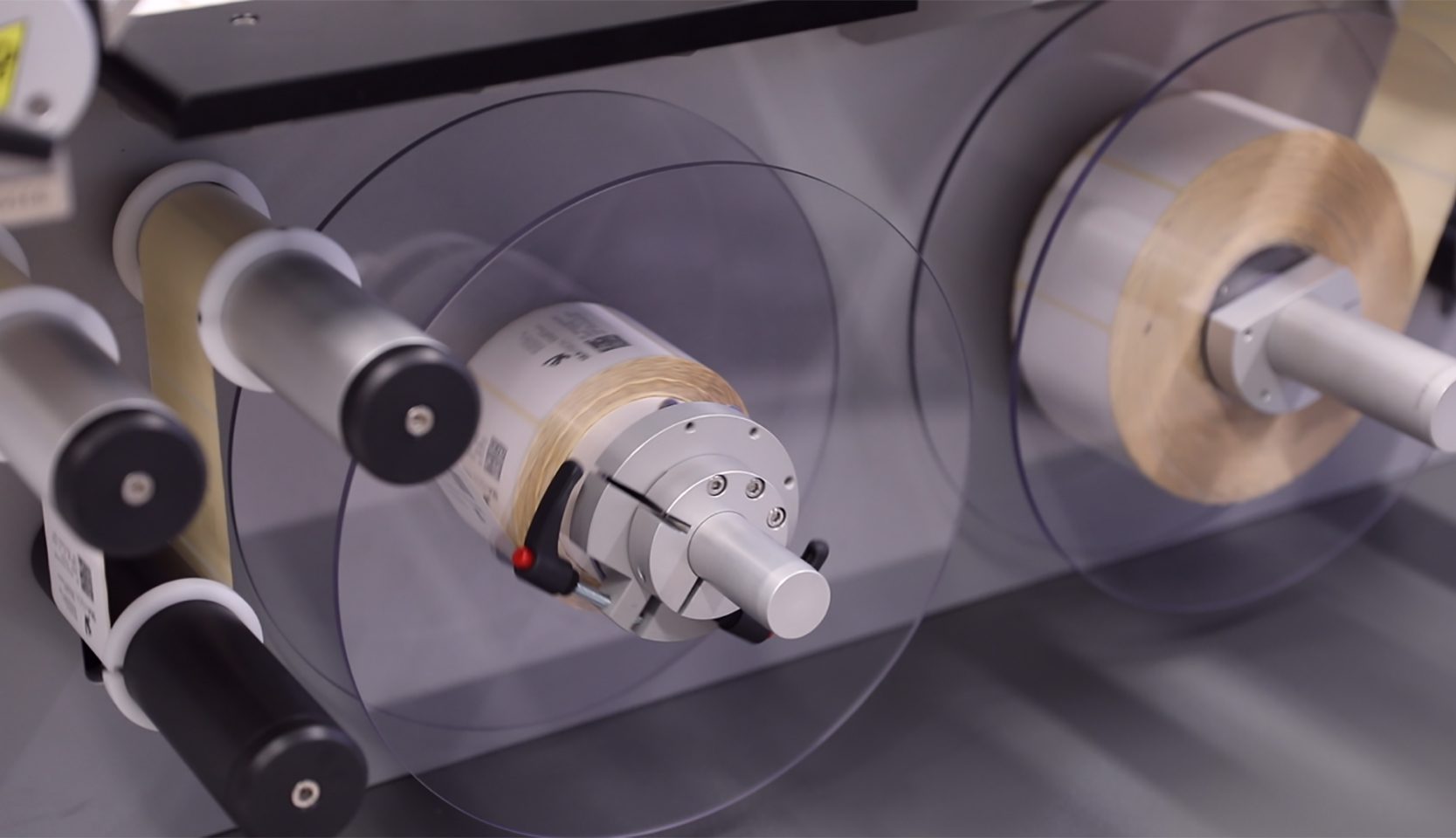

The label reel rewinding and unwinding are automatic: after a labels roll is finally printed and inspected, it can be used on the production line.

A user-friendly HMI interface guarantees real-time label inspection results, and carries out clear, precise work instructions to guide operators.

This compact pharmaceutical label printing machine can be placed everywhere very easily, ensuring a non-invasive procedure; the wheels help to move it around the production site, giving the possibility to serve multiple packaging lines at the same time. The label reel unwinding is automatic to guarantee a safe and smooth process.

The system is specifically designed for the pharmaceutical market, and it is compliant with the industry regulations, with user access regulated by FDA 21 CFR part 11 and annex 11. All events are registered by the software in an audit trail file to keep track of all the security-relevant activities.

The continuous Software development follows Gamp 5, to always improve products quality and consistency.

The workstation includes Tracker, a powerful serialization system, completely developed in-house by SEA Vision. Tracker is capable to perform complete sets of inspection on 1D, 2D codes, data matrix and OCV/OCR controls on characters in a completely trusty way and allows the complete serialization and aggregation of the products according to GS1 standards and worldwide Track&Trace regulations (e.g. DSCSA for the USA, EU-FMD for Europe). Tracker communicates with Level 3 for serial numbers provisioning and posting operations.

The latest generation systems of SEA Vision include a virtual PLC, in always more performant software. Logi-C is the new software tool developed by SEA Vision to program complex automation logic. The smart tool is useful to perform different automation processes, with the help of guided instructions. Logi-C works just like a traditional PLC, adding more power and configurability.

Trackroll is an essential purchase for businesses that need to comply quickly with aggregation and serialization requirements for small to medium-sized production.

The solution’s software is natively integrated with Yudoo, the 4.0 pharmaceutical software suite for the full management of automation processes, digital quality, data analysis and for Track&Trace. A digital hub that is everywhere accessible through a secure-access web interface or dedicated devices.

A scalable and modular suite, including tools for automation (centralized management of production, workflows and timesheet), for the digital quality (creation of paperless systems, support systems for line clearance operations), for data analysis (analysis of production data, business intelligence dashboard, condition monitoring and predictive maintenance) and for Track and Trace (complete solutions for Level 3 and 4 of serialization, monitoring of serialization operations).

Yudoo offers multiple advantages such as the possibility to centralize production formats and data, avoiding duplicates and reducing work time. The suite can connect to existing company systems to retrieve updated data exactly from where they are.

SEA Vision provides an extensive product portfolio of natively integrated solutions. Vision, traceability and data management solutions for pharmaceutical packaging lines are developed with a common approach to obtain a seamless ecosystem.