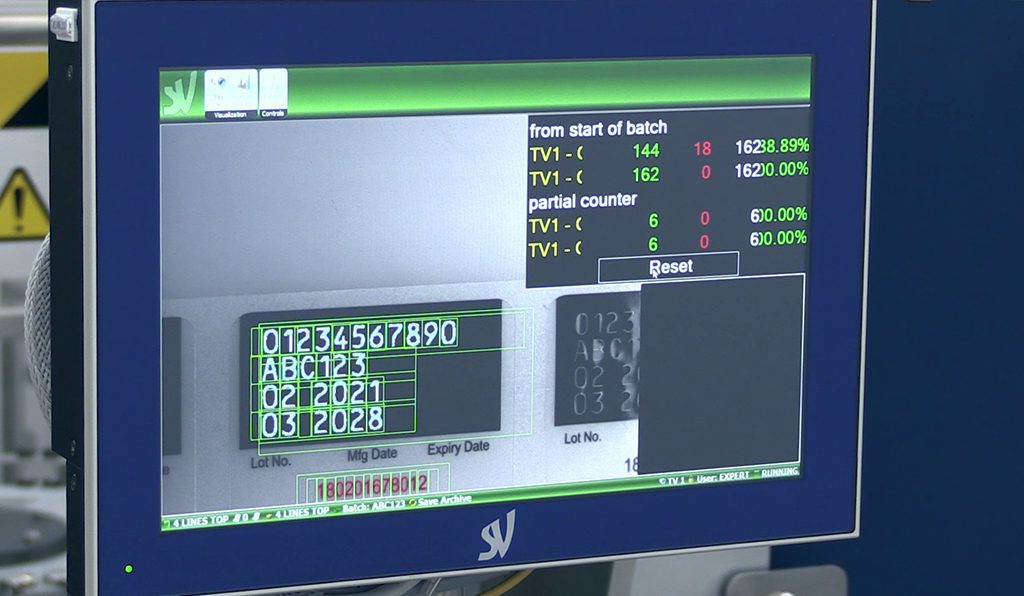

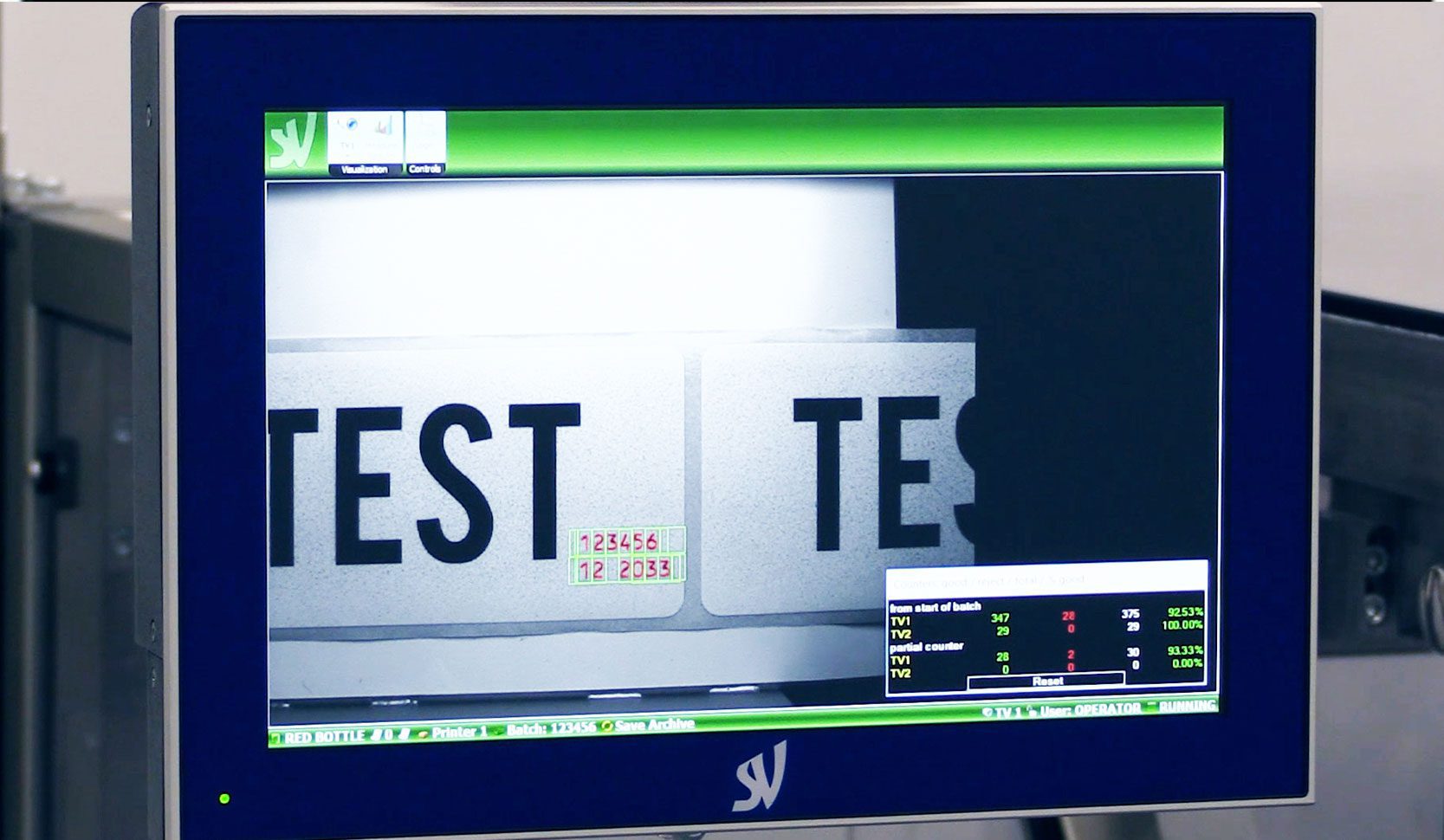

Databox is the vision system designed to perform not serialized linear and 2D codes inspection (eg. pharmacode barcodes and others), OCV/OCR characters checks on variable data and special customized controls on the packaging aspect by using the programmable measures tool.

It is a complete solution, delivering the best powerful inspection performance in ultra-compact miniaturized hardware.

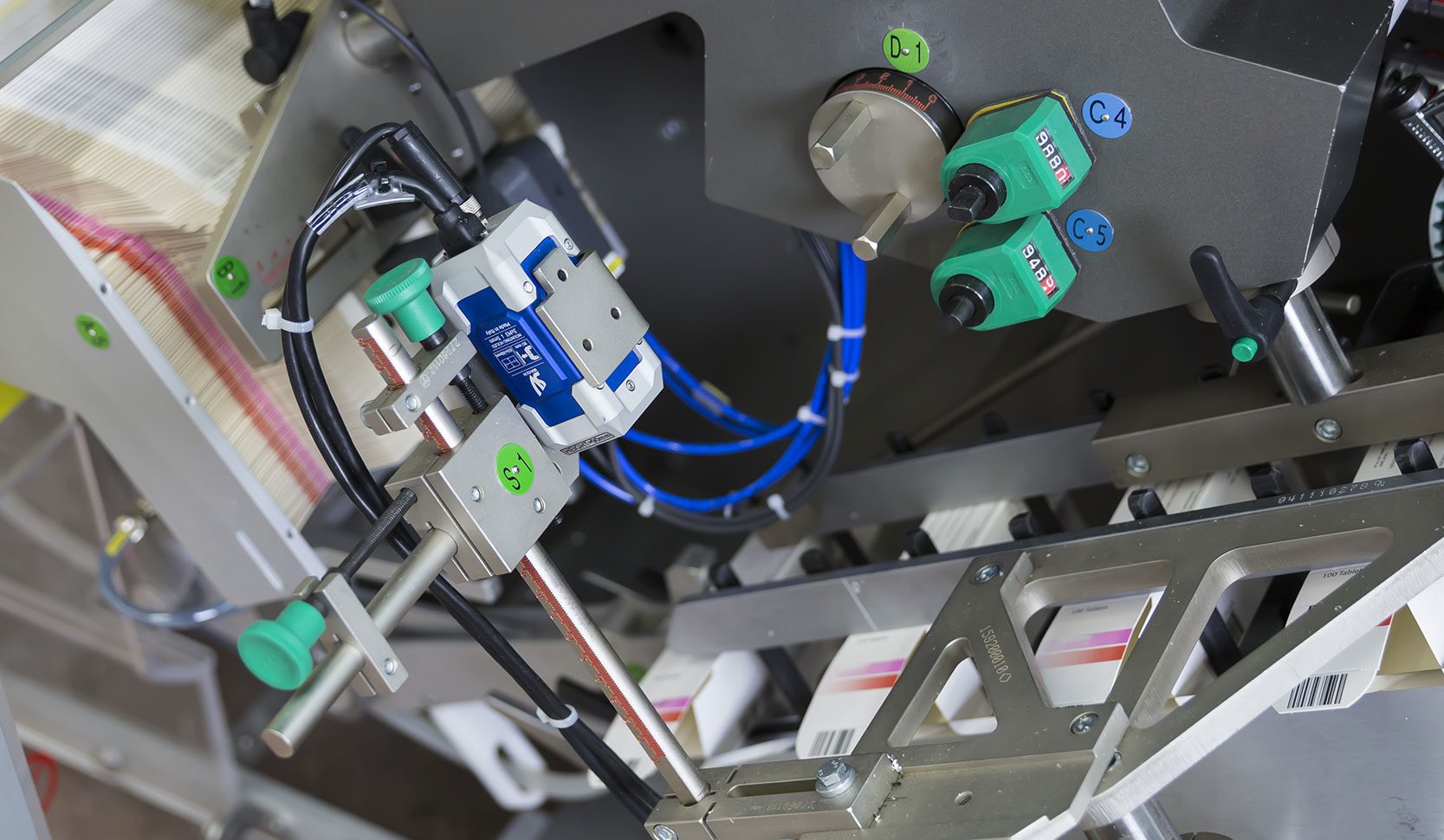

Originally designed for the integration into cartoning and labeling machines, Databox vision system today can perform controls on components and products feeders and buffers too.

Industrial, miniaturized hardware

Machine integration design

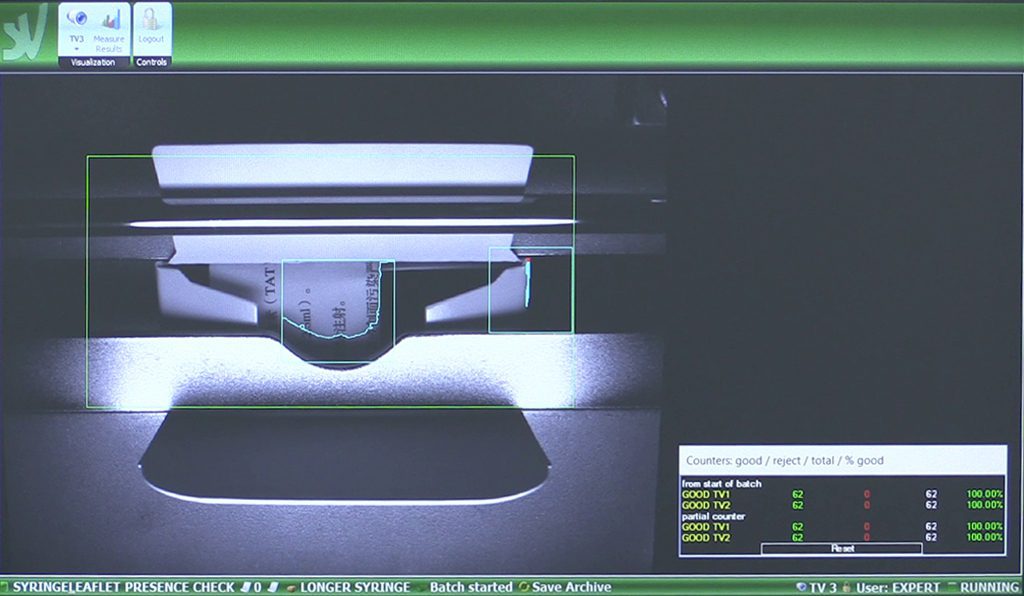

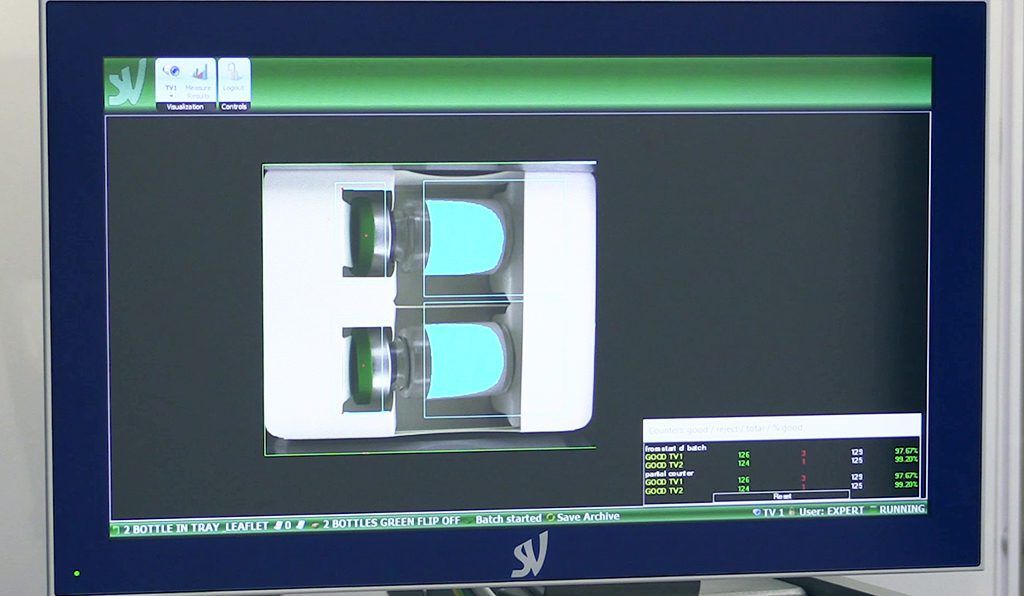

Programmable measure for custom inspection

Optimal controls on every product and material

Real time inspection results

Databox is the vision inspection system specifically designed for labelers, cartoners, feeding machines and buffers.

Able to control 100% of the product during the packaging process, it guarantees the highest production quality.

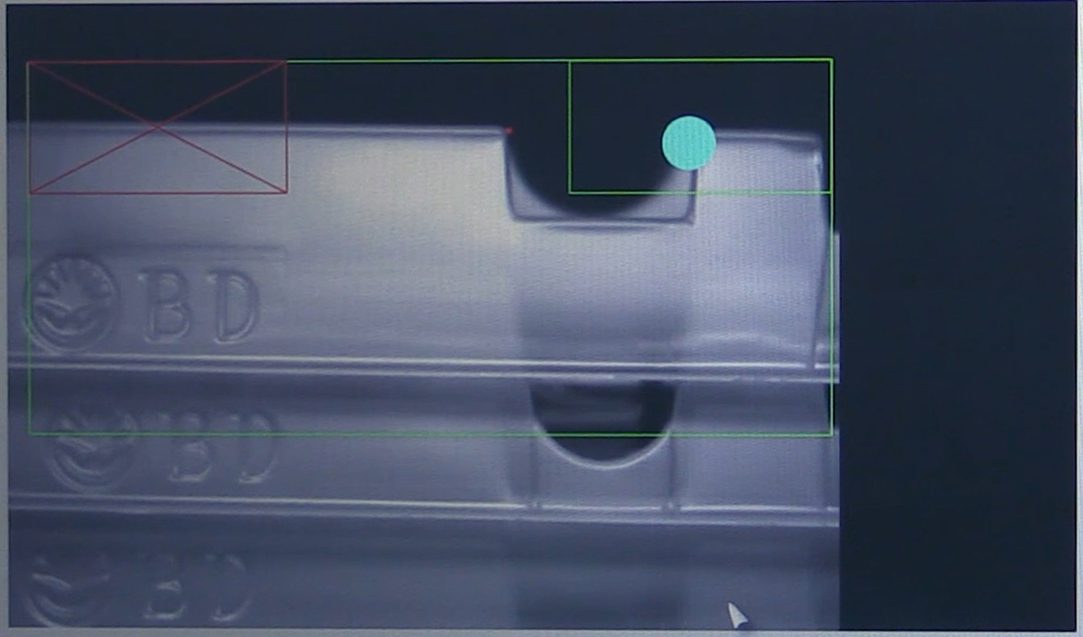

The HMI display shows in real-time the results of every check and, while 100% of products units are inspected, the vision system manages the rejection of each non-compliant items.

The system is a truly complete solution, consisting of a software integrated in a newly-designed compact hardware: industrial aluminum main unit and stand-alone capacitive touch-screen are combined with miniaturized camera cases with integrated illuminator, to shape the backbone of Databox.

Developed for adapting the new generation packaging machines of several models produced by different OEMs, the system can be integrated smoothly thanks to the automation logic, and without impacting the production speed.

SEA Vision’s expertise in integration is built on decades of experience working alongside machine manufacturers to satisfy the needs of pharmaceutical customers worldwide.

Such experience guarantees correct machine integration, accurate signal exchange management, and integrated automation and rejection logic.

Databox can be integrated on different machines, from entirely automated or semi-automated to modules with a low automation level.

The graphical oscilloscope allows the observation of signal patterns and keeps them under control, facilitating the diagnostical operation.

The entire process is handled efficiently, from the control execution to the rejection of defective products.

Databox is natively integrated with Yudoo, the 4.0 pharmaceutical software suite for the full management of automation processes, digital quality, data analysis and for Track&Trace. A digital hub that is everywhere accessible through a secure-access web interface or dedicated devices.

A scalable and modular suite, including tools for automation (centralized management of production, workflows and timesheet), for the digital quality (creation of paperless systems, support systems for line clearance operations), for data analysis (analysis of production data, business intelligence dashboard, condition monitoring and predictive maintenance) and for Track and Trace (complete solutions for Level 3 and 4 of serialization, monitoring of serialization operations).

Yudoo offers multiple advantages such as the possibility to centralize production formats and data, avoiding duplicates and reducing work time. The suite can connect to existing company systems to retrieve updated data exactly from where they are.

SEA Vision provides an extensive product portfolio of natively integrated solutions. Vision, traceability and data management solutions for pharmaceutical packaging lines are developed with a common approach to obtain a seamless ecosystem.